PROGROUP is one of the leading manufacturers of corrugated medium packaging paper (3 paper mills inn Germany) and converting solutions with multiple plants all over Europe.

In 2018 PROGROUP decided to build up a new paper mill in Sandersdorf-Brehna, Saxony-Anhalt (Germany), with a planned capacity of 750.00 t/year capacity (out of 100% recovered wastepaper) to provide paper to their converting- and box- plants, operation started in 2020 / 2021.

Due to the circumstances that no Public Effluent Treatment Plant (ETP) was nearby to the new paper mill site, and the fact that a tight project realization timeline was mandatory, the management of PROGROP decide to set a new benchmark in water saving and sustainability.

The new PM3 paper factory was so with designed with a fully closed water loop: all process water (used in pulping, stock preparation, paper machine, rinsing, etc.) is collected, treated in-on-site treatment systems, and reused in the process rather than discharged as effluent.

- The New PM3 paper compared to conventional paper mills, reduces fresh-water consumption by around 80%, saving about 3.7–3.75 million m³ of water per year, this is only possible because of the following facts.

- Freshwater is only used to compensate for Evaporation but not for the Process, and no Process Wastewater is discharged.

- Water Circuits at the PM and in the Stock Preparation plant are separated by a high consistency barrier (screw press) which secures to maintain different, controlled water qualities at the PM and in the Stock Preparation plant.

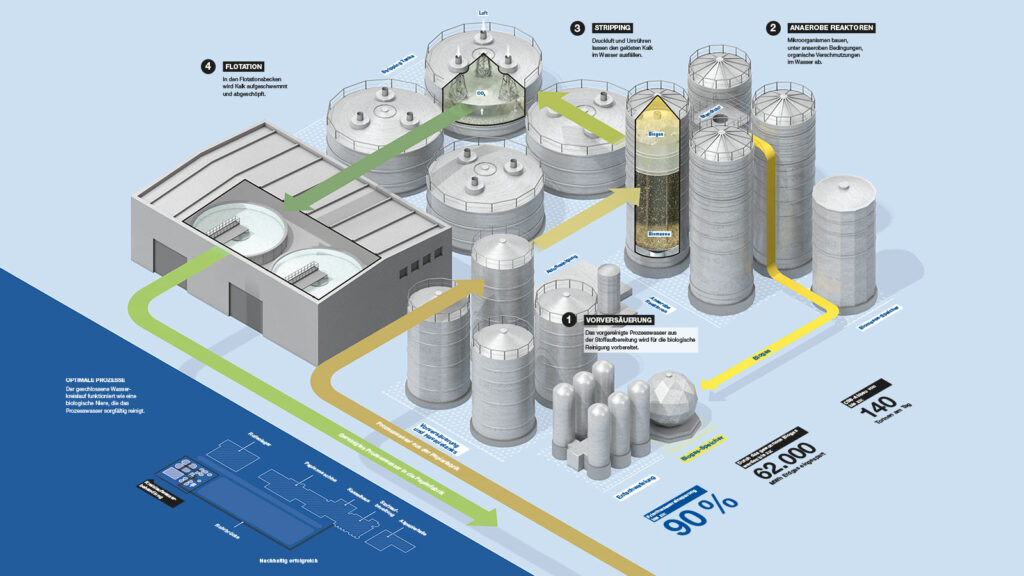

- Residual (Waste-) Waters from Stock Preparation runs “online “ through a “Bio Kidney- Water Treatment Plant” which consist of:

- Chemical- Physical Treatment (precipitation, flocculation and solids removal)

- Pre- Acidification and Flow- Storage Management

- High Performance R2S Anaerobic Bio Reactors

- Post Treatment and Lime Removal ( Flas Aeration, Conditioning, Lime Removal)

- Biogas Treatment and Conditioning for Boiler-Use

The Clarified Water form the “Bio Kidney- Water Treatment Plant” is used on the Paper Machine and in the Stock Preparation plant, the water.

The New “Bio Kidney- Water Treatment Plant” has provided from the beginning extraordinary performance with approx. over 80% COD reduction, up to 30 t/day Lime Removal.

The High Performance R2S Anaerobic Bio Reactors produce significant amount of anaerobic pellets, while operating reliably and without failure for Years, providing significant amount of Biogas for the onsite incinerating power plant.

Thanks to the commitment and great teamwork between PROGROUP and Meri, the realized plant and the performance since start up sets new benchmarks in performance and sustainability for the paper industry.