The Spanish SAICA Group and Meri have been teamworking for 3 decades on common projects mainly for WSR and Reject-Handling Subsystems in several mill locations.

Saica owns a paper mill in Champblain-Laveyron, France, which produces ca. 500.000t/year of testliner (brown recycled liner) and recycled fluting (medium) papers for corrugated packaging, using 100% recycled fiber as raw material.

Saica has done significant investments to replaces most fossil gas with biogenic / waste-based fuels (biomass), cutting emissions and exposure to gas markets, installing a Bubbling Fluidised Bed Boiler (BFBB) designed to co-fire waste wood plus paper-industry coarse rejects (an RDF-like fraction).

The capacity of the BFB Boiler is ca. 105.000 t/year end-of-life wood and up to 50.000 t/year of RDF like prepared Rejects and Residuals form wastepaper stock preparation.

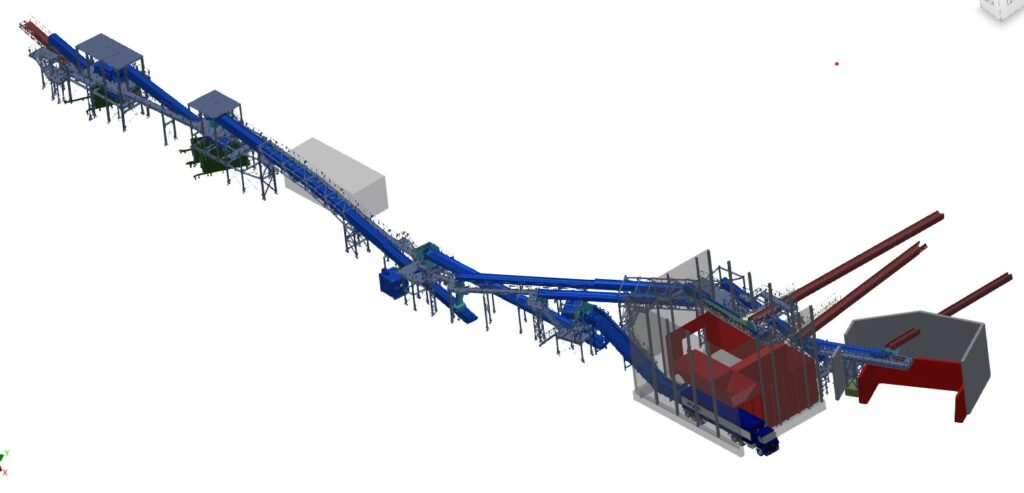

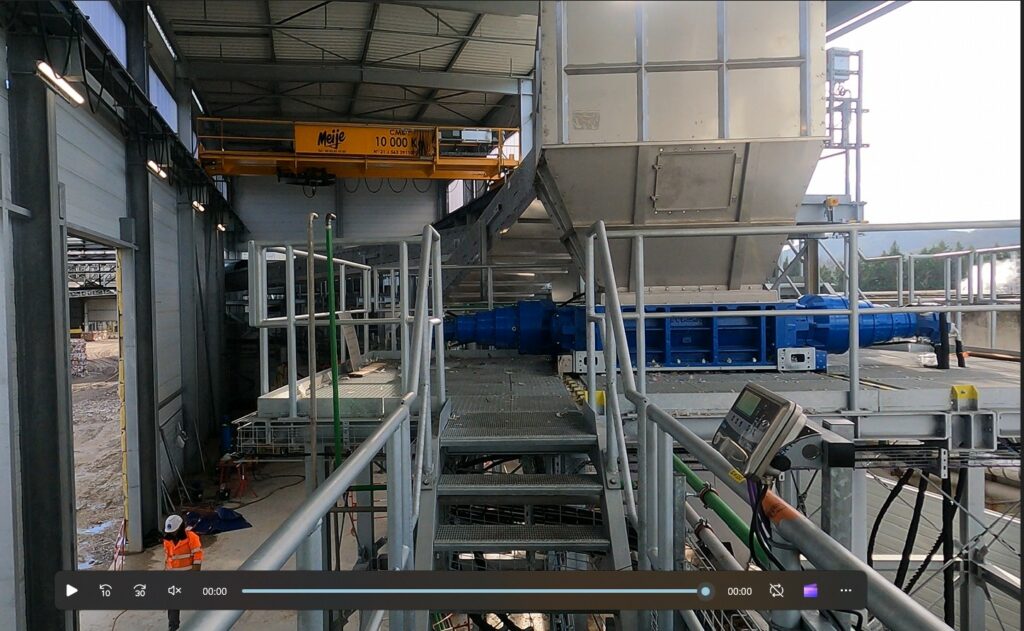

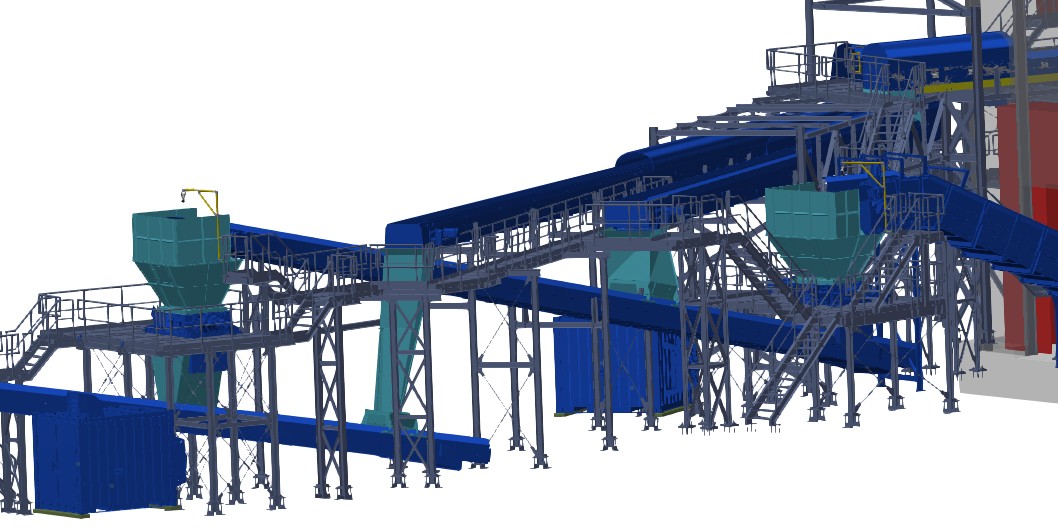

In a close teamwork Meri has delivered for this Project Engineering, Equipment, and all Services for an integrated Reject and Residual handling plant, with the target to Prepare, Transport, and Produce a RDF-like Fuel from Ropes, Plastic Rejects, Residuals for continuous incineration in the BFBB biomass boiler.

The scope included multiple equipment as Special MBC Belt Conveyors, multiple stage LION Twin Shaft Shredders, with low speed, hydraulically driven rotating knives, to cut and subsequently separate the fractions, Plastic, Fiber and Metall by the means of Fe- Magnetic and Eddy Current separation.

The plant build and assembled in 2023, started up in 2024 and runs since then successfully to full satisfaction.

Thanks to the commitment and great teamwork between Saica and Meri Teams, the realized plant is producing fuel from waste since its start-up, supporting mill’s reduction of CO2 footprint.