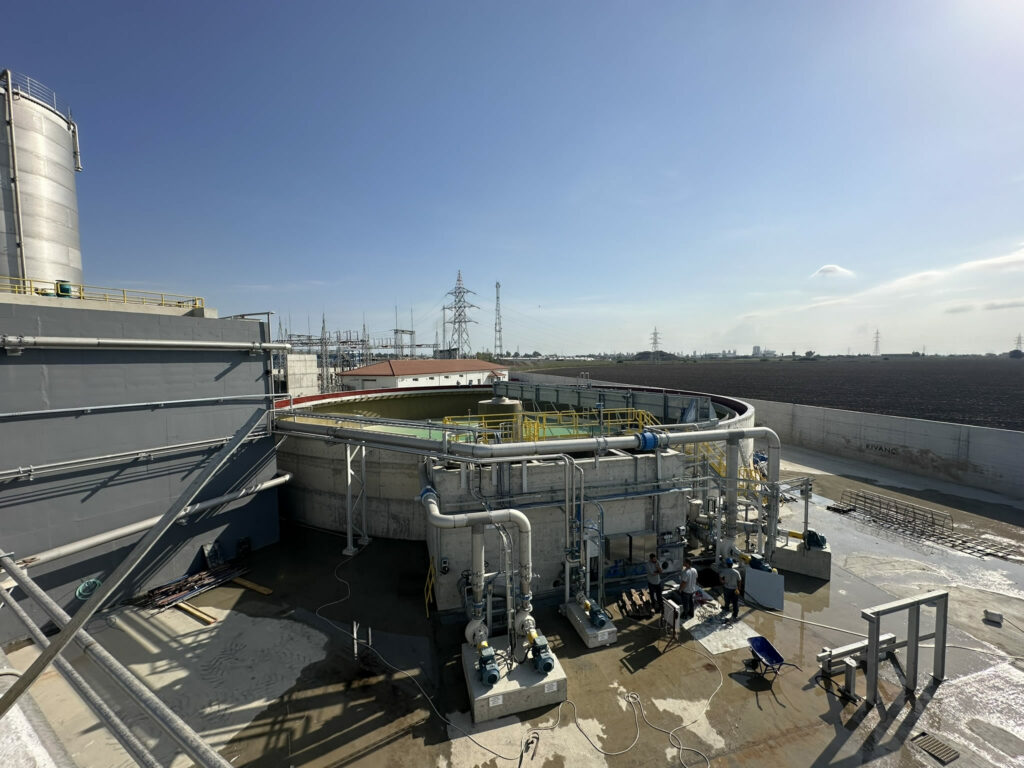

For the New Paper Mill Kıvanç Kağıt Üretim – PM 1 (Adana, Turkey) Meri has provide the Technology , Engineering, Equipment and Services for a Brand New Multi Stage Chemical- Physical and Anaerob & Aerob Biological Treatment.

The Effluent Treatment Plant (ETP) is executed with the latest State of the Art Technology and Equipment form Meri which secures the highest Environmental and Sustainability Standards.

The ETP process is fully integrated with the Stock Preparation which is the heart of the paper production supplying fiber to the paper machine.

The ETP handles up to 7.200 m³/day with a maximum COD Load of 57.000 kg/day.

The following Meri Process Technologies are installed:

- “Smart Loop” with Elephant Disc Thickener and Deltapurge DAF to secure

- Pre-Conditioning Stage consisting of Buffer, Cooling Stage and Pre-Acidification

- Anaerobic Biological High Performance R2S Reactor for highest COD removal and Bio Gas generation.

- Lime Removal Stage including Flash Aeration and special Limetrap Technology

- Aerobic activated sludge stage

- Secondary Treatment (Sedimentation)

- Tertiary Treatment (Coagulation, Flocculation and Dissolved Air Flotation)

- High Performance Sludge Treatment for primary sludge form stock preparation and secondary sludges from ETP consisting of Blue Drain Gravity Thickener and 2 RSP Screwpress units.

The plant was ordered in 2021, build and assembled from 2022 until 2024, started up in 2024 and runs since then successfully.

Meri would like to thank the KIVANC-Team and the Meri Employees for their commitment and successful work.